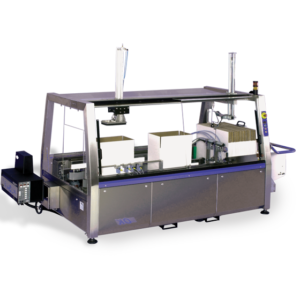

Superformer Case Erectors

Our range of heavy-duty stainless steel automatic case erectors have a unique and simple case forming process with the easiest and fastest case size changes in the market. Having the ability to change sizes quickly whenever you need to makes our case erector machines the best way to stay on top of changes in production. These automatic case erectors are simple to use for any operator, so you don’t have to waste time figuring out a complex mechanism. They’re extra durable to ensure their long-term viability, and the materials we use are easy to clean and sanitize—perfect for food products and other perishables.SUPERFORMER SF1

Automatic Case Erector & Bottom Taper

These premium, heavy duty case erectors are available in several frame sizes for a wide range of single and double wall HSC and RSC cases (AFM and FOL optional)

SUPERFORMER SF1-HM

Automatic Case Erector & Bottom Gluer

These premium heavy duty hot-melt case erectors are available in several frame sizes for a wide range of single and double wall HSC and RSC Case (AFM and FOL optional)

SUPERFORMER SF3

Automatic Case Erector

The Superformer SF3 erects RSC cases, folds the bottom flaps and closes them with

tape. Unique features of this machine include stainless steel finish, automatic

case squaring system, easy size change, tape and case monitoring.

Features | Benefits |

Quick and easy size change. Quick and easy size change. |  Increased production efficiency and flexibility. Increased production efficiency and flexibility. |

Automatic case squaring system. Automatic case squaring system. |  Consistency for automatic lines and enhanced cosmetics. Consistency for automatic lines and enhanced cosmetics. |

Tape and case monitoring package. Tape and case monitoring package. |  Operator friendly and reliability. Operator friendly and reliability. |

Single frame, in line design. Single frame, in line design. |  Ease of setup, training and operation. Ease of setup, training and operation. |

Stainless steel exterior finish. Stainless steel exterior finish. |  Clean & durable finish, preferred in food and other industries. Clean & durable finish, preferred in food and other industries. |

TECHNICAL SPECIFICATIONS | |

| Case range: | Superformer SF1S 20.00” x 16.00 x 20.00” (L x W x H) max. |

Superformer SF1 24.00” x 20.00” x 24.00” (L x W x H) max. | |

Superformer SF1L 31.50” x 20.00” x 24.00” (L x W x H) max. | |

| Speed: | Superformer SF1S Up to 15 cases per minute. |

| Superformer SF1 Up to 13 cases per minute.Servo Option – Up to 20 per minute | |

| Superformer SF1L Up to 9 cases per minute. | |

| Taping heads: | OK 55 high quality taping head with open tape feed path, suitable for 2” (50mm) wide tape (max.) and 14” (350mm) diameter rolls. OK 75 3″ (75mm) optional. |

| Case magazine: | Horizontal, belt driven, indexing magazine, length 40” (1000mm). 60″ (1500mm) optional. |

| Electric: | 480V, 3 Phase, 60Hz. Other voltages to requirement. 400V, 3 Phase, 50Hz. Other voltages to requirement. |

| Pneumatic: | 80-100 psi (6 – 8 bar), 1/2” supply. Clean, dry and unlubricated air. |

| Controls: | Allen Bradley or Siemens PLC controls with operator fault finding display. Signals for low tape, no tape, tape not applied, low case magazine, and empty case magazine. |

| Finish: | Stainless steel frame and exterior, plated and painted interior. |

| Machine Handling: | Right to left or left to right to requirement. |

Features | Benefits |

Quick and easy size change. Quick and easy size change. |  Increased production efficiency and flexibility. Increased production efficiency and flexibility. |

Glue and case monitoring. Glue and case monitoring. |  Operator friendly and reliability. Operator friendly and reliability. |

Single frame, in line design. Single frame, in line design. |  Ease of setup, training and operation. Ease of setup, training and operation. |

Stainless steel exterior finish. Stainless steel exterior finish. |  Clean and durable finish, preferred in food and other industries. Clean and durable finish, preferred in food and other industries. |

TECHNICAL SPECIFICATIONS | |

| Case range: | Superformer SF1M-HM 18.00″ x 14.00″ x 16.00″ (L x W x H) max. Superformer SF1-HM 24.00” x 20.00 x 24.00” (L x W x H) max. |

| Speed: | Up to 15 cases per minute. |

| Hot-melt applicator: | Nordson Pro Blue 7 hot melt system or to requirement. |

| Case magazine: | Horizontal, belt driven, indexing magazine, length 40”(1000mm). 60″ (1500mm) optional. |

| Electric: | 480V, 3 Phase, 60Hz. Other voltages to requirement. 400V, 3 Phase, 50Hz. Other voltages to requirement. |

| Compressed air: | Constant 80-100 psi, 0.5 CF per cycle, 1/2″ supply, clean, dry and unlubricated air. |

| Controls: | Allen Bradley or Siemens PLC with operator fault finding display. |

| Finish: | Stainless steel electrical enclosure and cover sheets. |

| Machine Handling: | Right to left or left to right to requirement. |

Features | Benefits |

Quick and easy size change. Quick and easy size change. |  Increased production efficiency and flexibility. Increased production efficiency and flexibility. |

Automatic case squaring system. Automatic case squaring system. |  Operator friendly and reliability. Operator friendly and reliability. |

Tape and case monitoring package. Tape and case monitoring package. |  Consistency for automatic lines and enhanced cosmetics. Consistency for automatic lines and enhanced cosmetics. |

Stainless steel finish. Stainless steel finish. |  Clean and durable finish, preferred in food and other industries. Clean and durable finish, preferred in food and other industries. |

TECHNICAL SPECIFICATIONS | |

| Case range: | Superformer SF3 8.00” x 6.00“ x 4.00” (200x150x100mm) (L x W x H) min. 24.00“ x 20.00” x 24.00“(600x500x600mm)(L x W x H) max. Max Case Blank Width 42.00” (1050mm) |

| Speed: | Up to 15 cases per minute. |

| Taping Heads: | OK 55 high quality taping head with open tape feed path, suitable for 2” (50mm) wide tape (max.) and 14” (350mm) diameter rolls. |

| Case magazine: | Horizontal, belt driven, indexing magazine, length 40” (1000mm) |

| Electric: | 480V, 3 Phase, 60Hz standard. Other voltages to requirement. |

| Controls: | PLC controls with 6” (150mm) Color Touchscreen HMI. |

| Finish: | Stainless steel frame, covers and electrical enclosure, plated and painted interior. |

| Machine Handling: | Right to left or left to right to requirement. |

See Our Machines in Action

Superformer SF1 Case Erectors – Tape

Superformer SF1 Servo Case Erectors – Tape Higher Speed

Superformer SF1-HM-FOL Hot Melt Case Erector

Superformer SF1-HM Case Erectors – Hot Melt Glue

Superformer SF1-HM-FOL w/ Superliner SL220 Case Liner

Options

Customize your machine

- Smaller or Larger Case Sizes

- 60″ (1500mm) Long Case Magazines

- Touch Screen Display Unit

- OK 75 Taping Head for 3” (75mm) Wide Tape

- Higher Speed Case Erectors

- Hot-Melt Case Erectors

Get in Touch with a Representative

We’re here to help you customize your machine.