Whenever your business creates products, your team must package and send those goods to retailers or consumers. This process is important but can be slow and inefficient when you rely on human operators. Watch out for these three signs it’s time to automate your packaging line so you can make your business much more efficient.

Packaging News and Innovations

Here at Ok International, we’ve been serving different businesses and industries for over 40 years now, meeting all their packaging system needs. However, we didn’t get to where we are today through luck. We’ve accumulated expertise and knowledge of our industry by being at the forefront of innovations in the packaging industry.

Technology doesn’t slow down, and you shouldn’t let your business fall behind. We’ll keep up with all the food packaging news and trends for you, so you can come to us, and then we can create modern custom solutions that work for you. On top of developing packaging automation systems for you, we’ll stay up to date with these industry changes and continue to improve to meet the changing needs of your industry.

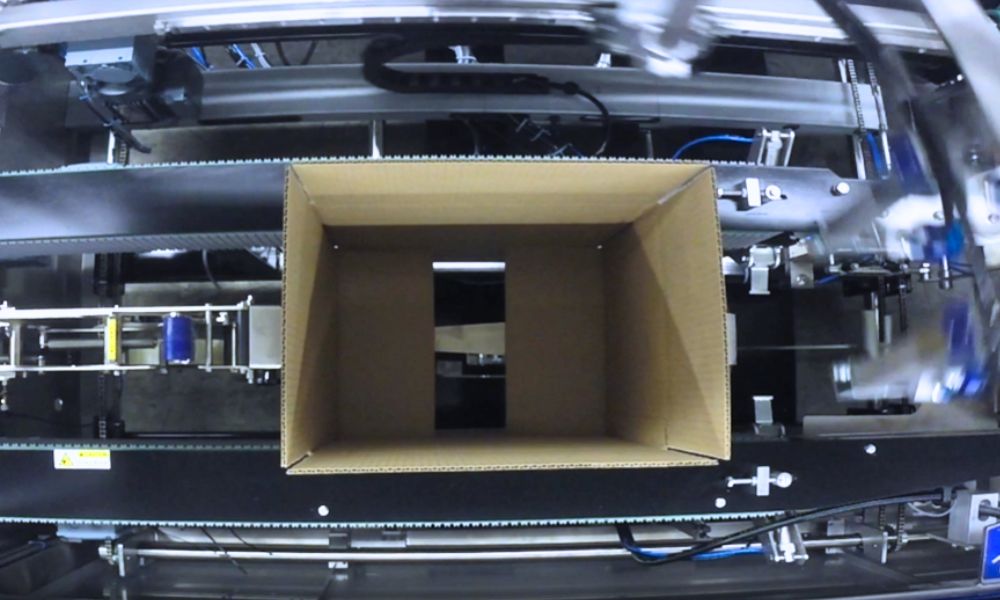

Case Erector

Cardboard, a key component in case erectors, is responsible for the manufacturing of boxes that safeguard and convey products. The use of high-quality cardboard in these systems can greatly influence their overall functionality and life span. Settling for inferior cardboard could lead to expensive complications later. Poor-quality cardboard can break or tear apart, leading to damage as well as case erector damage, and that’s on top of the delays this breakage also creates. Ultimately, using poor-quality cardboard may save money in the short term, but in the long term, you end up paying more for repairs and business interruptions. This potential makes it crucial for businesses to invest in high-quality cardboard boxes, as it directly impacts the efficiency of their case erector machines.

3 Reasons Investing in a Complete Packaging Line Saves Money

Many businesses use packing lines to send products to customers, but packaging lines can look very different from business to business. Companies sell different goods, and each one has different packaging requirements. Unfortunately, it’s a great source of inefficiency. Investing in a complete packaging line saves money for many reasons, so invest in this process if you want your business to succeed.

3 Ways To Tell if a Jam Is a Mechanical or Material Issue

At every stage of production, jams are a common and costly problem. In everything from small-scale businesses to large-scale manufacturing operations, jams can lead to costly downtimes and decreased efficiency. Identifying the source of the jam is key to finding an effective solution, but it’s not always clear whether the jam is a mechanical or material issue. Thankfully, there are ways to tell so you can identify the issue, then fix it.

4 Interesting Facts About the Superformer Case Erector

Case erectors play a crucial role in any packaging line. With so many capabilities, they can empower your business, enhancing its efficiency, productivity, and performance. The Superformer case erector is a great example of this, but there’s a lot more to this machine than meets the eye. There are plenty of interesting facts about the Superformer case erector you might not know about. Learn them here so you can get the most out of this machine.

3 Reasons an Automated Packing Line Should Be Ergonomic

One of the best ways to push your business into the future and boost productivity is to embrace automated packing lines. They can simplify your business operations and let you and your team focus on more important parts of the manufacturing process, but there are some mistakes you can make with your packing. Your automated packing lines must be ergonomic because failing to account for ergonomics can hurt your packing line’s and team’s efficiency.

4 Reasons Packaging Equipment Redundancy Is Important

Equipment redundancy refers to having multiple versions of the same equipment but not using all of them at once. It can seem excessive, but packaging equipment redundancy is important and has a lot of benefits for your business. If you’ve got the financial and physical resources to have equipment redundancy, you should pursue it.

3 Great Automatic Case Sealer Accessories To Consider

One of the best machines you can have in your packaging system is an automatic case sealer, but there’s only so much these machines can do by themselves. Businesses have different needs. To meet your business’s needs, you may want to consider some great automatic case sealer accessories. These accessories will help you streamline your packaging system and ensure you get your products out quickly and safely.

4 Basic Maintenance Tips for Bag Insert Machines

Bag inserter machines eliminate the need for pre-made bags, making them a great addition to any packaging assembly line. However, like every other machine, they don’t operate perfectly forever. The devices can wear down, things can stick, or any number of other issues can arise. But with these basic maintenance tips for bag insert machines, you can keep your system running smoothly for years.

3 Reasons Case Erectors Are Essential for Business Growth

If you want your business to succeed and grow, you must have grand visions and an understanding of your market. You must also keep a careful watch over the smallest details of your business. No one said it would be easy, but if you know what machines and layout decisions you need, you can rest easy knowing you left your business in good hands. A case erector is essential for business growth because you can have on your floor without worrying about it. Instead, you can shift your attention to more important variables your business faces.

4 Things To Know When Designing Packing Lines for Liquids

Liquid packaging requires an efficient layout and machinery. This task can be overwhelming if you’re new to the industry. We’re here to help you work through the process and provide advice on creating the best system. Here are four things to know when designing packing lines for liquids.

3 Ways To Prolong the Life of Your Packaging Machine

Proper maintenance can keep your packaging machine operating effectively and efficiently for years. You pay significant money for these systems and want to ensure they last as long as possible. Here are three ways to prolong the life of your packaging machine.